Approach

We take pride in our flexible approach to the product design process. It enables us to produce a tailored work program specific to the unique requirements of each client. The key stages are detailed below.

STAGE 0

Defining the brief

The first step of every project is to define the brief, budgets, and timings, as well as any other points that are of particular importance to the prospective work program. This will usually entail a sit down meeting including the Glenelg team, the client and any other important stakeholders. Glenelg will then provide a detailed proposal for the client to sign off against before further work progresses. There is no cost associated with this stage.

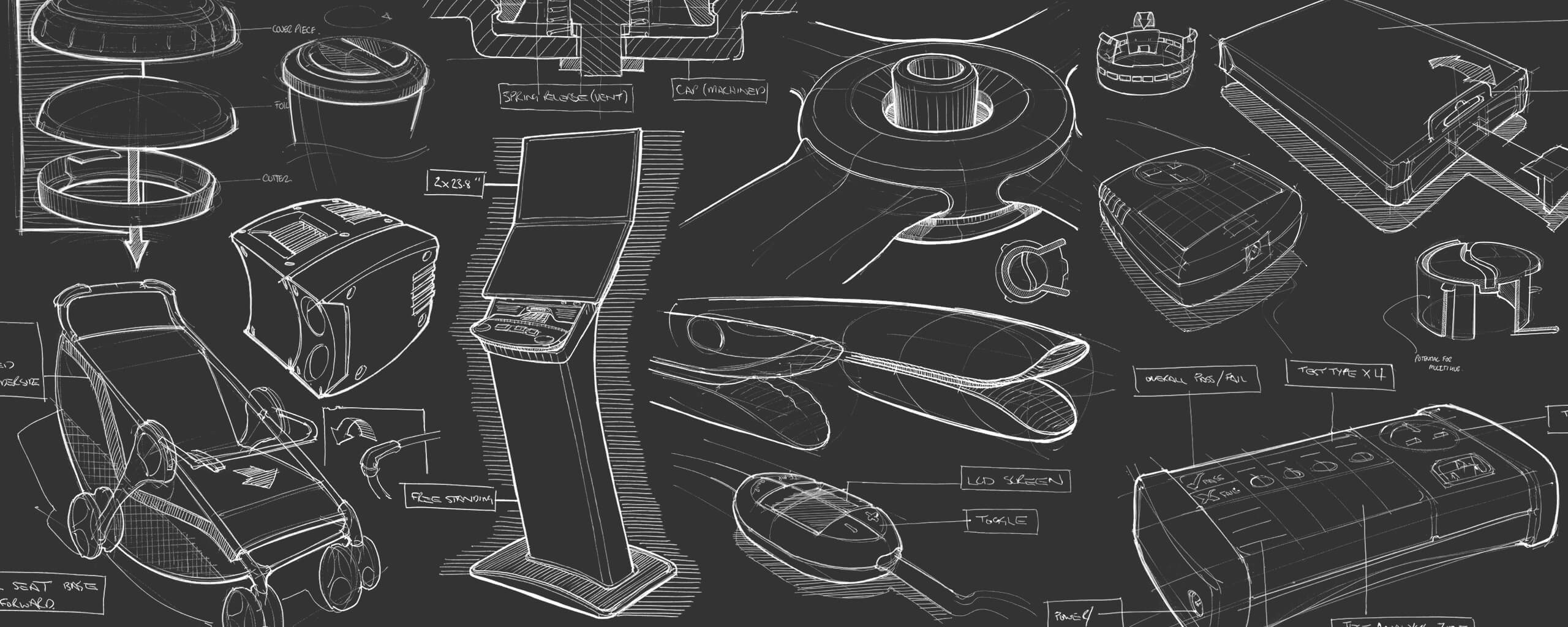

STAGE 1

Concept Generation

At the beginning of the product design process it is important to visualize as many ideas as possible. Our team of designers will work up a number of concepts based on your brief, combining innovative thinking with a realistic assessment of any manufacturing constraints. Firstly, we develop a wide range of concepts – ideas generation. Next, we evaluate these ideas against screening criteria, i.e. investment budget, product cost, etc. Finally, we define key attributes and present lead concepts.

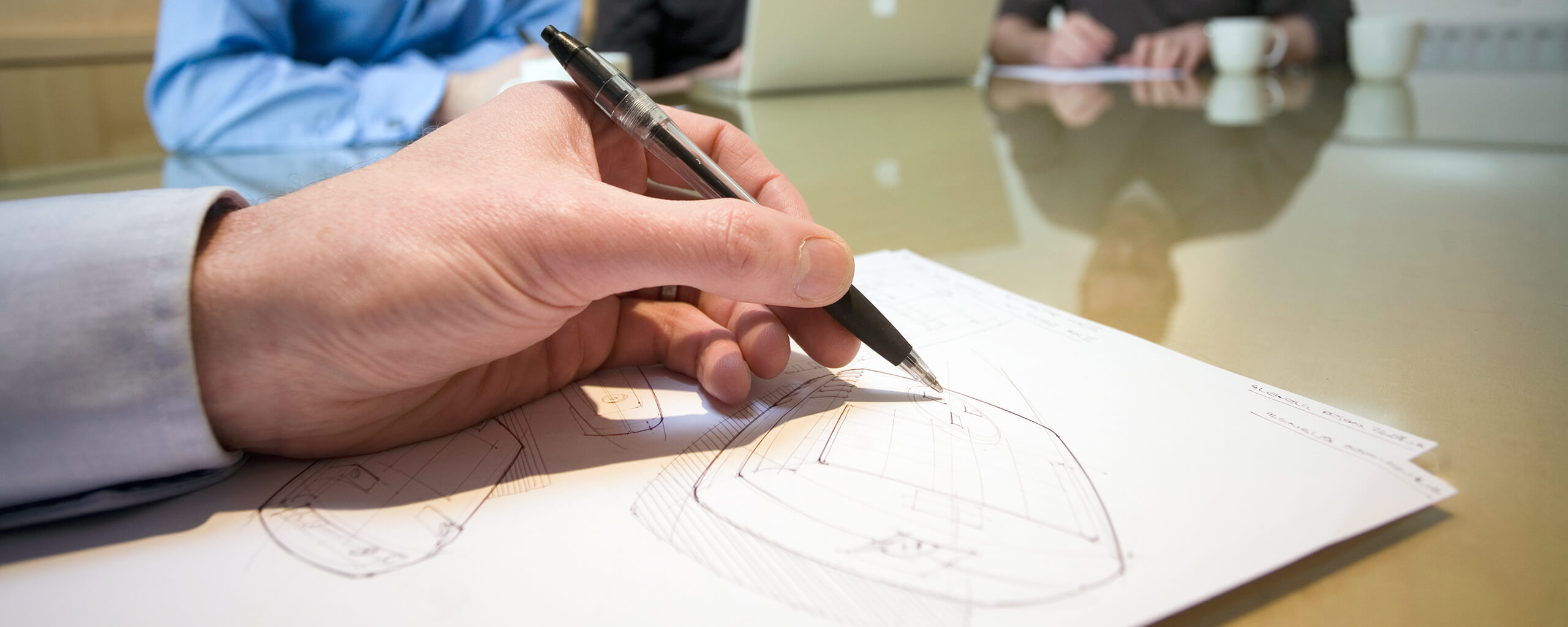

STAGE 2

Concept Development

Glenelg will optimise design detail based on client feedback, and these proposals may be validated in a number of ways. This could include 3D visuals, rig models, or 3D prints, which may be used to conduct qualitative research.

STAGE 3

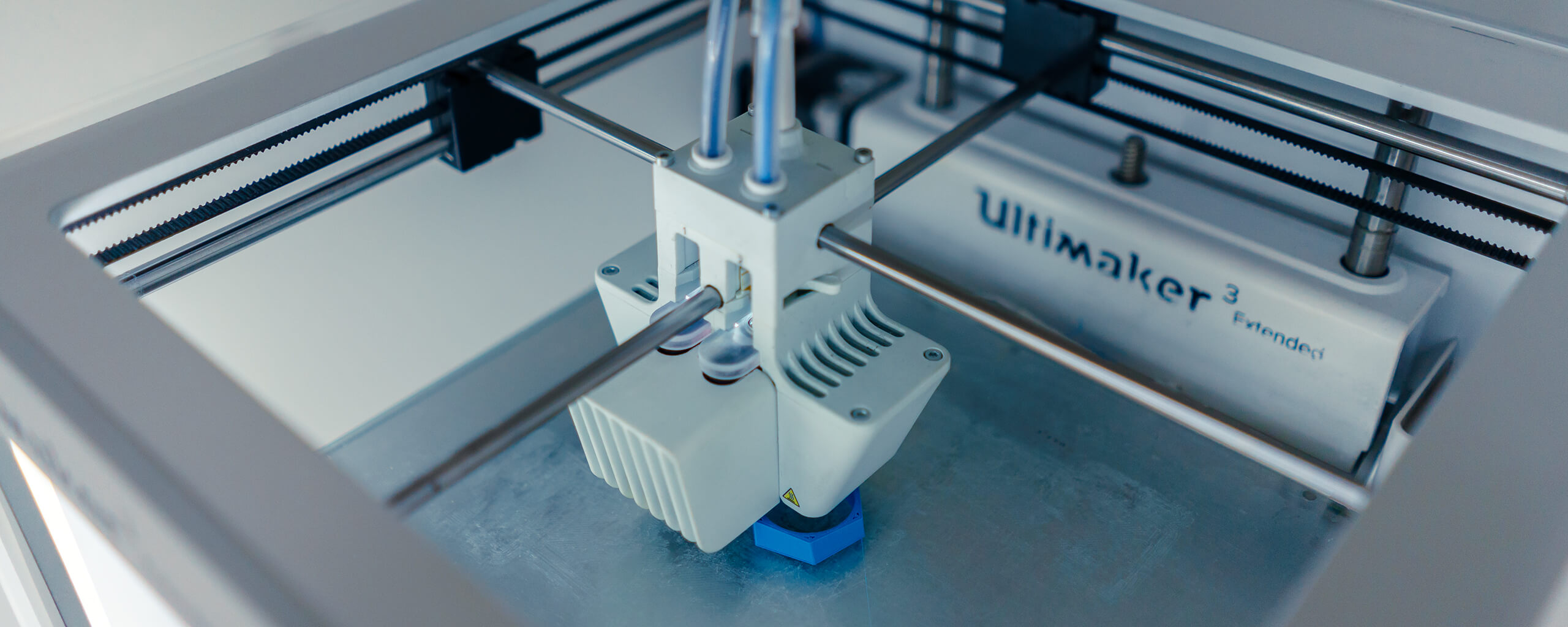

Prototyping

Glenelg are able to produce a wide range of prototypes. These may include quick 3D prints to gauge form and function, presentation models, or complete design assemblies in production materials. We have a raft of in-house resources, and links to prototyping specialists both locally and in the Far East. This enables us to cost effectively produce whatever you need to best test and showcase the developing product to your customers.

Prototyping may include, for example, rig building, 3D printing, presentation models, vacuum cast replicas, or machined working samples in intended production materials.

STAGE 4

Refinement

Through iterative development and prototyping we refine your product to a state suitable for production. Our process is collaborative and we work closely with our clients and manufacturing partners to make sure each detail is carefully considered before moving ahead. At this stage we encourage our clients to invest in end user feedback to make sure no valuable insights are missed.

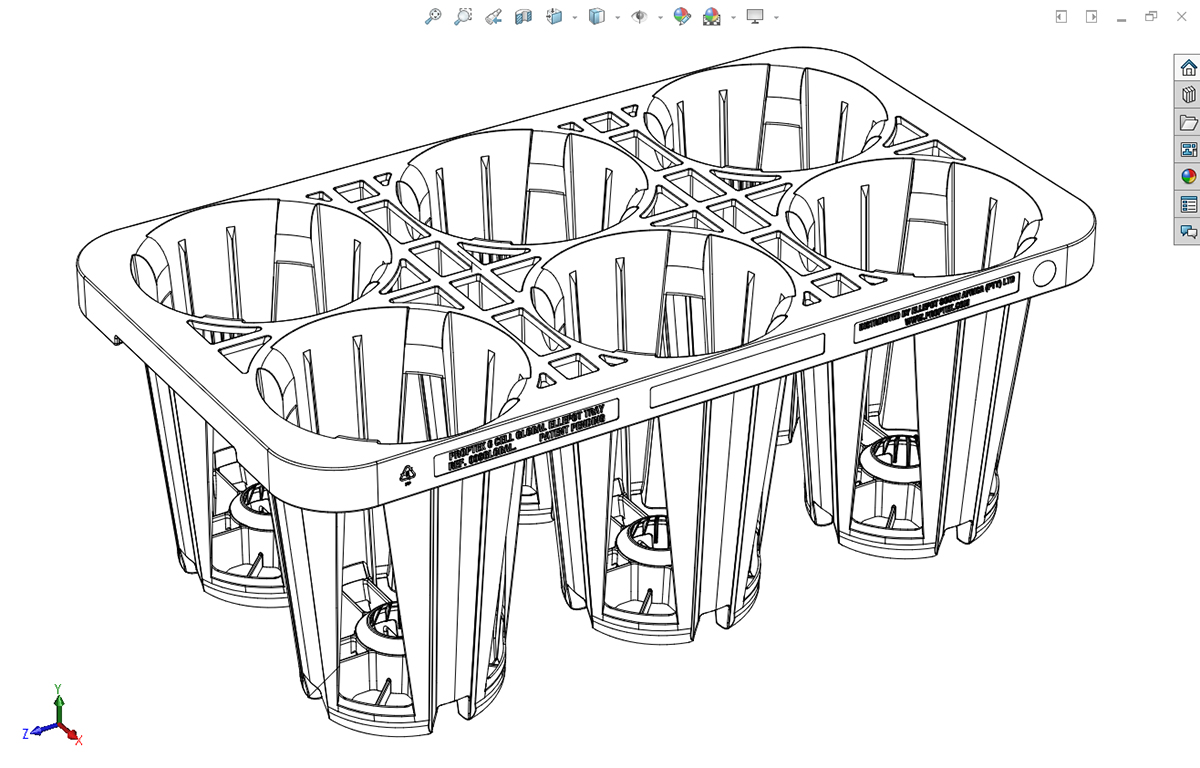

STAGE 5

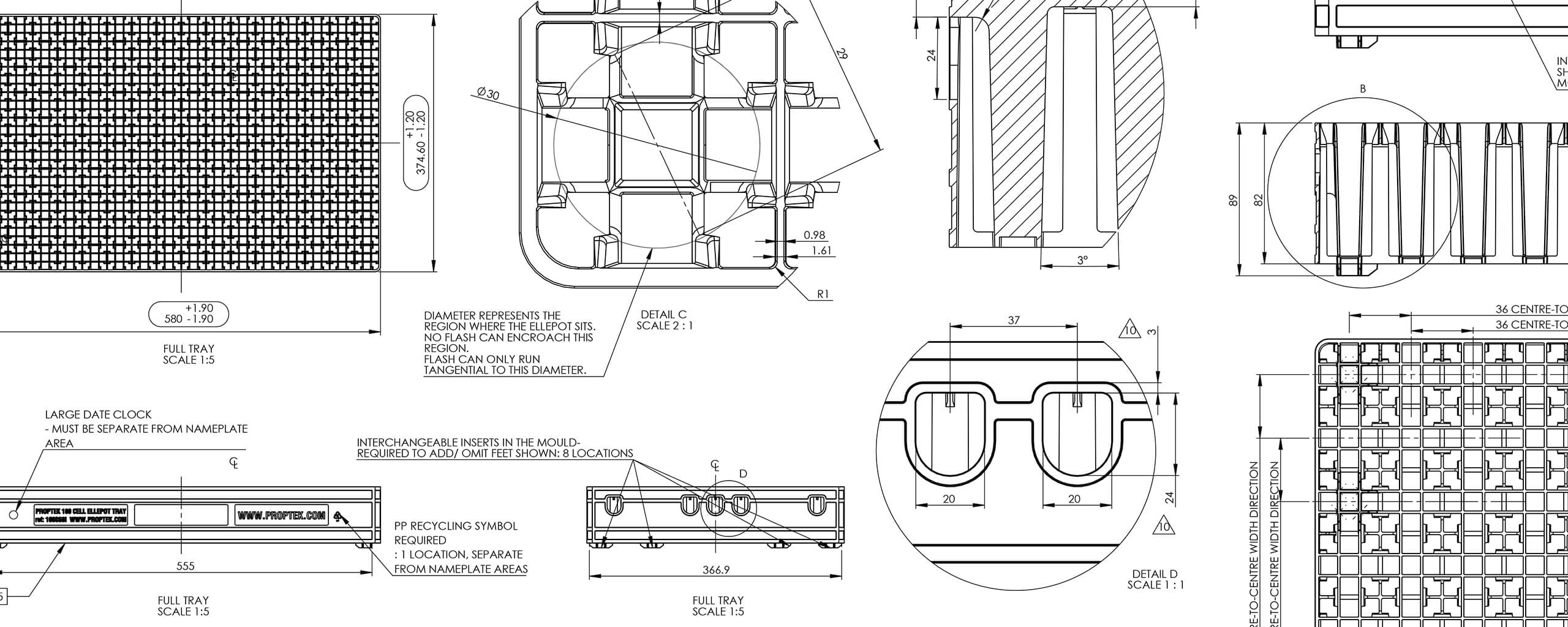

Specification

Glenelg will produce a detailed design specification suitable for taking the finished product to production. This usually includes a full set of 3D CAD and associated 2D drawings along with a complete bill of materials / processes. Further documents may also be produced at this stage, for example a product assembly guide to aid the production process.

STAGE 6

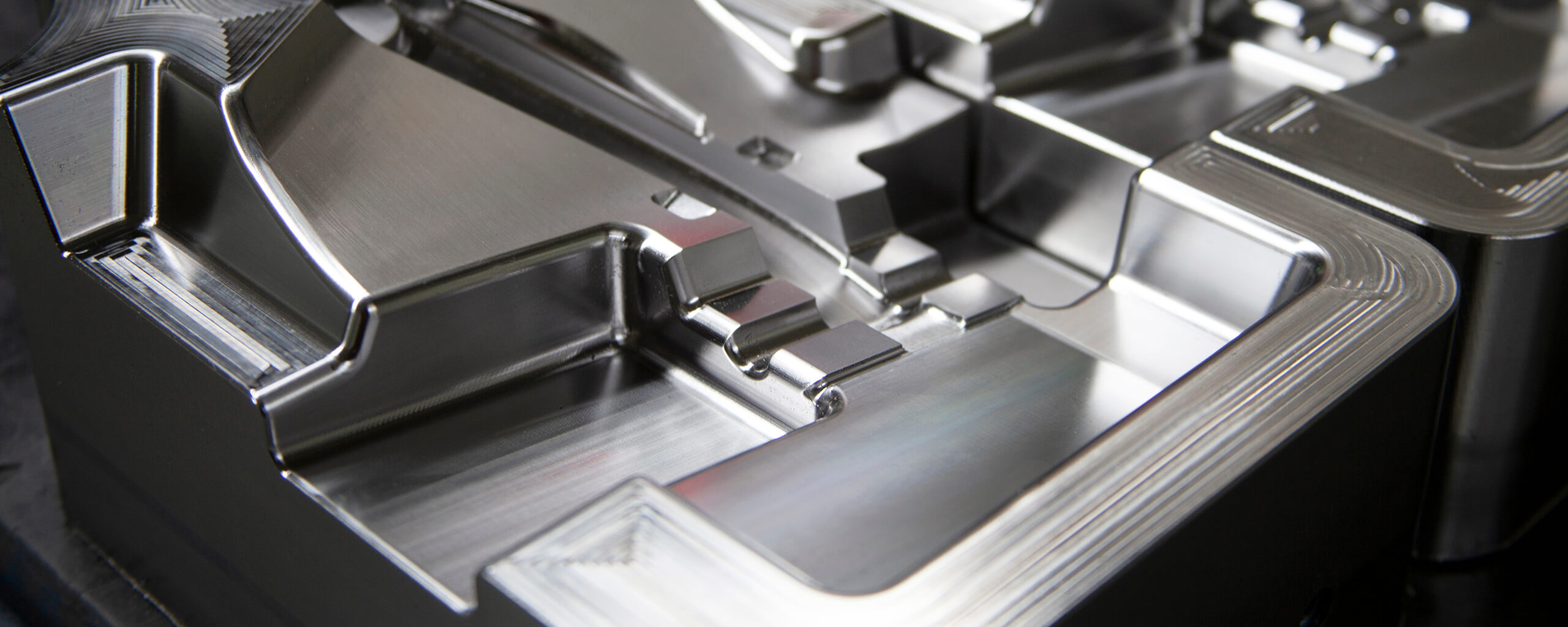

Production

Turning a functional prototype into an off the shelf product can be a daunting prospect. We will work alongside you to make sure you get the best quality at a price to suit your budget and volume requirements. Our work across a range of sectors has provided us with invaluable experience in managing production and allowed us to build strong relationships with many trusted partners.

STAGE 7

Added Value

We offer a range of additional services outside of the core product design process. Our goal is to provide each client with a seamless experience tailored to their individual needs.

Most of the items below are handled in-house. Should outsourcing be required, we are able to provide timely and competitively priced solutions due to strong links with like-minded local businesses.